Part 5: When the model is „finished“

I had the privilege of accompanying Tom Steiner and Michiel Stolp on parts of their journey to the acceptance test of the class 03.10 offered jointly by BMB/Bee's Modellbahn and Kiss Modellbahnen Deutschland. This opportunity gave me a valuable insight into the workshops of various manufacturers and their production processes, which would otherwise not have been possible for me. I am very grateful for this, also on behalf of our readers.

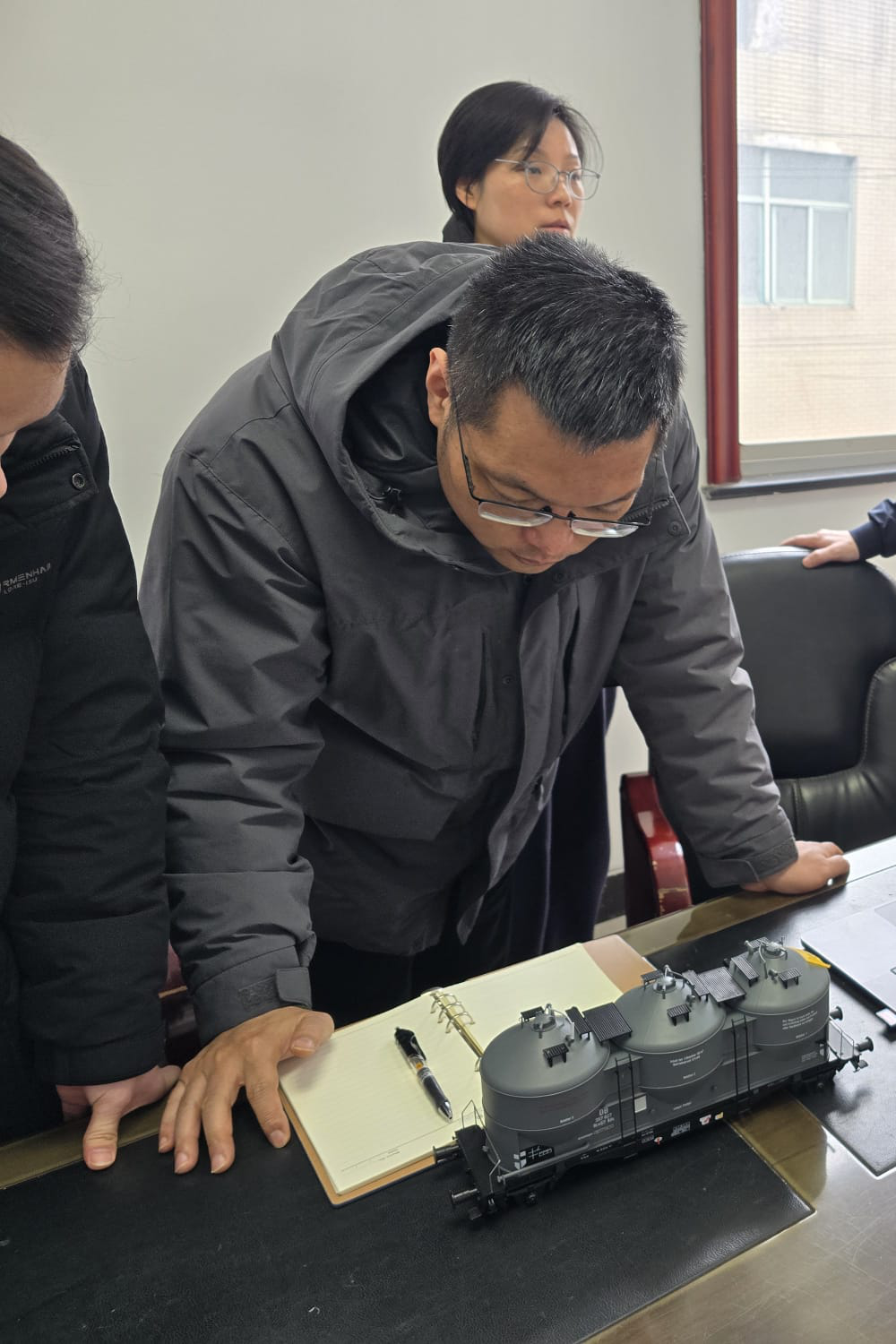

Acceptance is a sensitive moment and involves a lot of effort. This is where it is decided whether months of work meet expectations - or whether improvements need to be made. It shows very clearly how responsibility is distributed between client and producer and how communication works when details don't fit.

When defects are discovered during sensitive vehicle inspections, manufacturers attach great importance to carrying out repairs directly on site. If this were not carefully organised, customers would either have to live with quality defects or have the manufacturer pay for costly repairs. Returning the vehicles to the manufacturer would simply be unprofitable due to the double shipping and customs costs and would not be viable for any manufacturer.

This rare opportunity to experience the process not just from reports, but directly, is unique for all of us.

Now some impressions of the model reviews and the final acceptance of the 03.10 series. I hope you enjoy them.

Discussions on other projects also took place outside of the final inspection.